Vitrified Tile Systems utilize precision industrial ceramic units with pre-formed spacer lugs and the most advanced chemically resistant, antimicrobial setting and grouting materials. This achieves outstanding performance and unparalleled aesthetics for Food, Beverage, Dairy, Pharmaceutical, and Chemical Processing facilities.

Vitrified Tile floors are non-absorbent, hygienic, safe, durable, and provide industry-leading life-cycle economics. These systems utilize state-of-the-art techniques that accelerate the installation process, giving critical time back to today’s fast paced construction schedules.

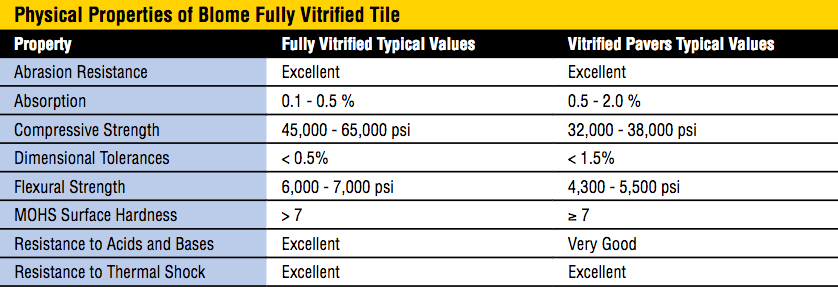

In addition, these systems provide optimal aesthetics, uniformity, and durability. Vitrified tiling combines high compressive strength and low absorption with immunity to impact and thermal shock.

These tiles are manufactured by Zahna Fliesen.